Every internal combustion engine, whether in a car, truck, generator, or marine vessel, needs a reliable way to start. This is where the starter motor comes into play. Though small in size compared to the engine it cranks, the starter motor is one of the most critical components for initiating engine operation. Without it, the powerful machinery we depend on daily wouldn’t even begin to move.

What is a Starter Motor?

A starter motor is an electric motor that rotates the internal combustion engine to begin the combustion cycle. It turns the engine’s crankshaft until the engine can sustain its own operation. Once the engine starts running, the starter motor disengages automatically.

Starter motors are found in a wide range of vehicles and equipment, including:

- Cars and trucks

- Marine engines

- Diesel generators

- Construction machinery

- Agricultural vehicles

How Does a Starter Motor Work?

- Electrical Signal Activation

When the ignition key is turned or a start button is pressed, a signal is sent from the battery to the starter solenoid. - Engagement of Gears

The solenoid pushes a small gear (called the pinion) on the starter shaft to engage with the engine’s flywheel or ring gear. - Engine Cranking

The electric motor spins, turning the pinion gear, which in turn rotates the flywheel and cranks the engine. - Disengagement

Once the engine starts and the key is released, the pinion gear retracts, and the starter motor shuts off.

Types of Starter Motors

Electric Starter Motor

The most common type, powered by the vehicle’s battery. Simple and widely used.

- Gear Reduction Starter

Uses a gear system to provide high torque while reducing motor size. Ideal for heavy-duty diesel engines. - Inertia Starter

Uses a spinning mass to engage the flywheel. Common in older engine models. - Pneumatic Starter

Uses compressed air, especially in large marine or aircraft engines. - Hydraulic Starter

Reliable for remote or hazardous environments where electric systems are not preferred.

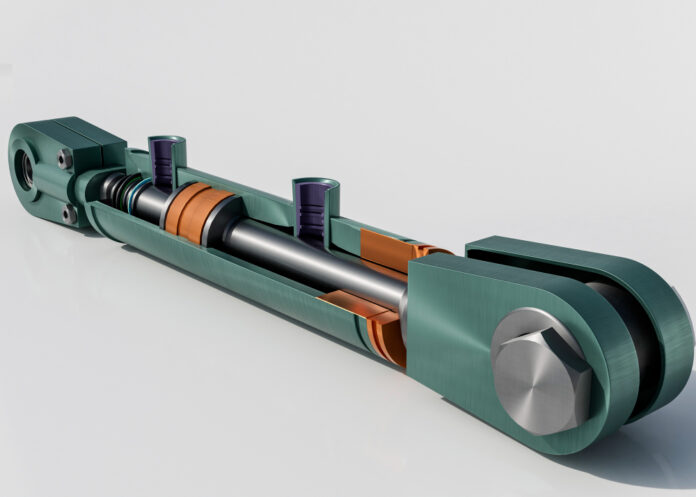

Components of a Starter Motor

- Armature: The rotating shaft inside the motor that creates mechanical motion.

- Solenoid: A magnetic switch that engages and disengages the pinion gear.

- Pinion Gear: The gear that connects the starter motor to the engine’s flywheel.

- Brushes and Commutator: Deliver current to the motor windings.

- Field Coils or Magnets: Create a magnetic field to turn the armature.

Signs of a Faulty Starter Motor

Clicking Sound: When the ignition is turned, but the engine doesn’t crank.

- Slow Cranking: Engine turns over slowly or weakly.

- Grinding Noise: Indicates a worn-out pinion gear or flywheel teeth.

- No Response: Starter doesn’t respond at all when the key is turned.

- Intermittent Starting: Sometimes the engine starts, sometimes it doesn’t.

Causes of Starter Motor Failure

Worn-out brushes or bearings

- Electrical connection issues or corroded terminals

- Battery voltage too low

- Damaged solenoid or faulty ignition switch

- Excessive heat from prolonged cranking

Maintenance Tips for Starter Motors

- Check Battery Health: A weak or dead battery can prevent the starter from functioning.

- Inspect Wiring and Connections: Ensure terminals are clean and tight.

- Listen for Unusual Sounds: Grinding or clicking sounds often indicate internal wear.

- Avoid Excessive Cranking: Continuous attempts to start can overheat the motor.

- Service Regularly: Especially important in marine engines and heavy machinery.

Starter Motors in Marine Applications

Marine engines often require heavy-duty, corrosion-resistant starter motors due to exposure to moisture and saltwater. These starters are specially sealed and built to withstand marine conditions. Reliability is key, especially for auxiliary engines or emergency generators at sea.

Maintenance Tips for Longer Starter Life

While starter motors are built to last, good maintenance habits can extend their lifespan:

- Keep battery terminals clean and tight: A weak battery or poor connection puts extra strain on the starter.

- Avoid holding the key too long: Cranking the starter motor for more than 10 seconds repeatedly can cause it to overheat.

- Inspect wiring and solenoid connections regularly for corrosion or looseness.

Starter Motors in Hybrid and Electric Vehicles

In modern hybrid and electric vehicles (EVs), traditional starter motors are often replaced by integrated electric drive systems:

- Hybrids use starter-generators or ISGs (Integrated Starter Generators) to start the engine silently and efficiently.

- EVs don’t use starter motors at all, since they don’t have internal combustion engines.

As automotive technology evolves, so does the role of the starter system.

Conclusion

The starter motor may seem like a small part of the engine system, but without it, nothing else in the system can function. It’s the initial spark that brings your machinery to life. Whether you’re maintaining a marine engine, a commercial truck, or a standby generator, a well-functioning starter motor is crucial to reliability, safety, and performance.